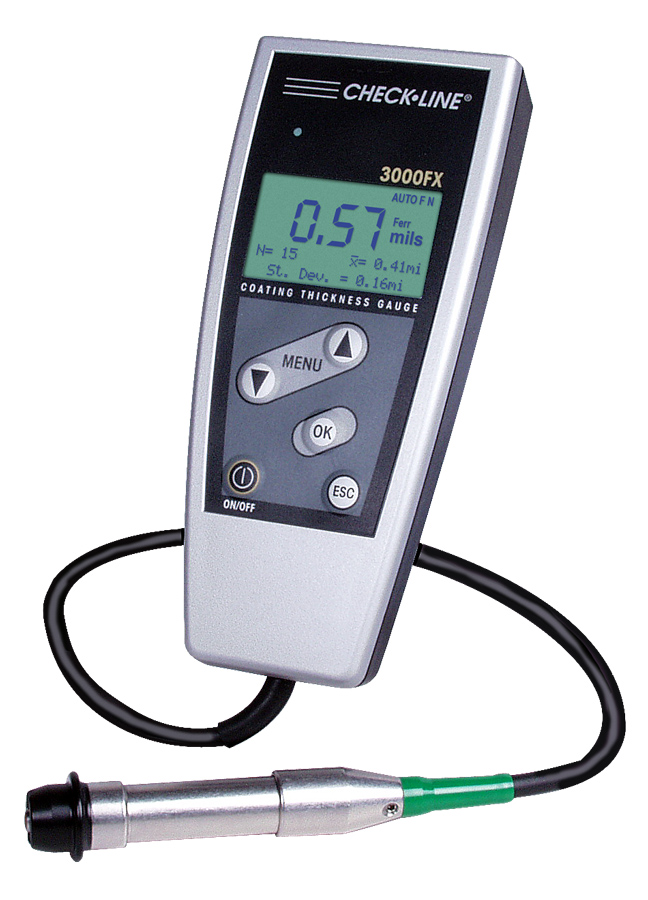

DCF-3000FX - Measures Coatings on Ferrous (steel, iron) Only

DCN-3000FX - Measures Coatings on Non-Ferrous (non-magnetic metal) Only

DCFN-3000FX - Combination Model, Measures Coatings on both Ferrous and Non-Ferrous metal

The Check-Line 3000FX Series coating thickness gauge is a powerful and precise coating thickness gauge designed for measurement of paint and non-magnetic coatings on steel and iron as well as paint and anodizing coatings on non-ferrous metals. All external probes are machined to ultra-high standards and utilize a unique, hard-metal probe tip which prevents probe wear.

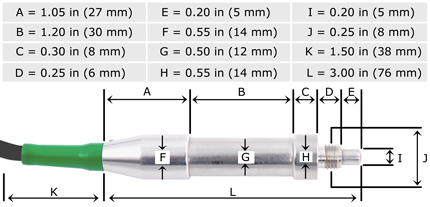

A v-notched footer provides a stable footing on small cylindrical parts, which can be removed to expose a "micro-probe" sensor perfect to measure on small surfaces and parts.

Where to use 3000FX Series?

Wherever coatings are applied – whether on visual and aesthetic grounds, to prevent corrosion protection, or for functional and mechanical reasons – the coating thickness represents an essential quality feature. The 3000FX Series is ideal for speedy, non-destructive and exceptionally precise coating thickness

measurement.

- The 3000FX Series is a compact, lightweight coating thickness gauge for operators who require both innovative and user-friendly measuring techniques

- The 3000FX Series ensures non-destructive coating thickness measurement on steel and non Ferrous metals

- Data transfer to a printer or PC takes place via an infra-red interface

- Up to 10 000 readings can be statistically evaluated: number of readings, mean value, standard deviation, minimum and maximum reading.

- The 3000FX Series identifies the substrate and activates the appropriate measuring procedure.

- Menu in a choice of three languages ensures ease of operation

- The uniform contact pressure of the sensor is kept to a minimum, preventing scratches and indentations to sensitive surfaces.

- Two optional high temperature footers for measuring on surfaces up to 150 °C/302 °F or up to 300 °C/572 °F

- Traceable Certificate Included at no additional cost

- 2 Year Warranty

| Minimum Radius for Convex Surfaces | 0.12" (3 mm) | |

| Minimum Radius for Concave Surfaces | 0.2" (5 mm) | |

| Minimum Headroom | 4" (100 mm) | |

| Minimum Sample Diameter | 0.2" (5 mm) | |

| Minimum Substrate Thickness - F | 20 mils (0.5 mm) | |

| Minimum Substrate Thickness - NFe | 2 mils (50 um) |

| Mils | |

| 0.00 - 9.99 mils | 0.01 mils |

| 10.00 - 24.98 mils | 0.02 mils |

| 25.00 - 49.95 mils | 0.05 mils |

| 50.0 - 60.0 mils | 0.1 mils |

| Microns (µm) | |

| 0.0 - 99.9 µm | 0.1 µm |

| 100.0 - 249.8 µm | 0.2 µm |

| 250.0 - 499.5 µm | 0.5 µm |

| 500 - 1500 µm | 1 µm |

| Measuring principle: | Magnetic induction principle (Ferrous) Eddy-current principle (Non-Ferrous) |

| Range | 0 - 60.00 mils 0 - 1500 µm |

| Accuracy | ±0.04 mils / 1µm + 1% of reading |

| Resolution | Refer to RESOLUTION TABLE, above |

| Display | back-light, 4-digit alphanumeric, digit height 10mm |

| Minimum Measuring Area | 0.2" x 0.2" (5 mm x 5 mm) |

| Minimum Curvature Radius | convex: 0.12" (3 mm), concave: 0.2" (5 mm) |

| Minimum Substrate Thickness | Ferrous: 20 mils / 0.5 mm Non-Ferrous: 2 mils / 50 µm |

| Calibration | factory calibration, zero calibration, foil calibration, offset-function: addition or subtraction of a constant value |

| Memory | 80 readings |

| Statistics Program | Number of readings, mean value, standard deviation, maximum and minimum reading of max. 10,000 readings |

| Data Output | Infrared IrDA Standard |

| Operating Temp. | 32 °F - 122 °F / 0 °C - 50 °C |

| Surface Temp. | 5° F - 140° F / -15° C - 60° C (standard) 5° - 302° F / 15° - 150° C (w/3000-HTF) 5° - 572° F / 15° - 300° C (w/3000-HTF-300C) |

| Storage Temp. | -4 °F to 140 °F / -20 °C to +60 °C |

| Power | 2 AA 1.5V |

| Dimensions | 5.6" x 2.5" x 1.2" (140 mm x 62 mm x 30 mm) |

| Weight | 7 oz (200 g) (gauge + probe) |

| Protection Class | IP 52 (proof against dust and dripping water) |

| Standards | DIN, ISO, ASTM, BS |

| Warranty | 2 Years |

| Color Coding | DCF =BLUE DCN = YELLOW DCFN = GREEN |

| Calibration Certificate | Included |

| Item | Description | Price | ||

|---|---|---|---|---|

Precision Coating Thickness Gauge, Measures Coatings on Ferrous Metals up to 60 mils / 1500 Microns | $1,445.00 | |||

Precision Coating Thickness Gauge, Measures Coatings on Non-Ferrous Metals up to 60 mils / 1500 Microns | $1,445.00 | |||

Precision Coating Thickness Gauge, Measures Coatings on Ferrous and Non-Ferrous Metals up to 60 mils / 1500 Microns | $1,745.00 | |||

| Accessories | ||||

3000-HTF | High Temp Footer for 3000FX / 3000PRO. 300° F / 150° C Limit | $75.00 | ||

3000-HTF-300C | High Temp Footer for 3000FX / 3000PRO. 572° F / 300° C Limit - Please contact us for pricing and availability. | $ | ||

Coating Thickness Gauge Probe Stand | $825.00 | |||

3000-FOOT | Standard Foot for 3000FX | $49.00 | ||

NIST Traceable Calibration Certificate | $100.00 | |||